3D Printing Terminology: A Beginner’s Guide to Key Terms and Concepts

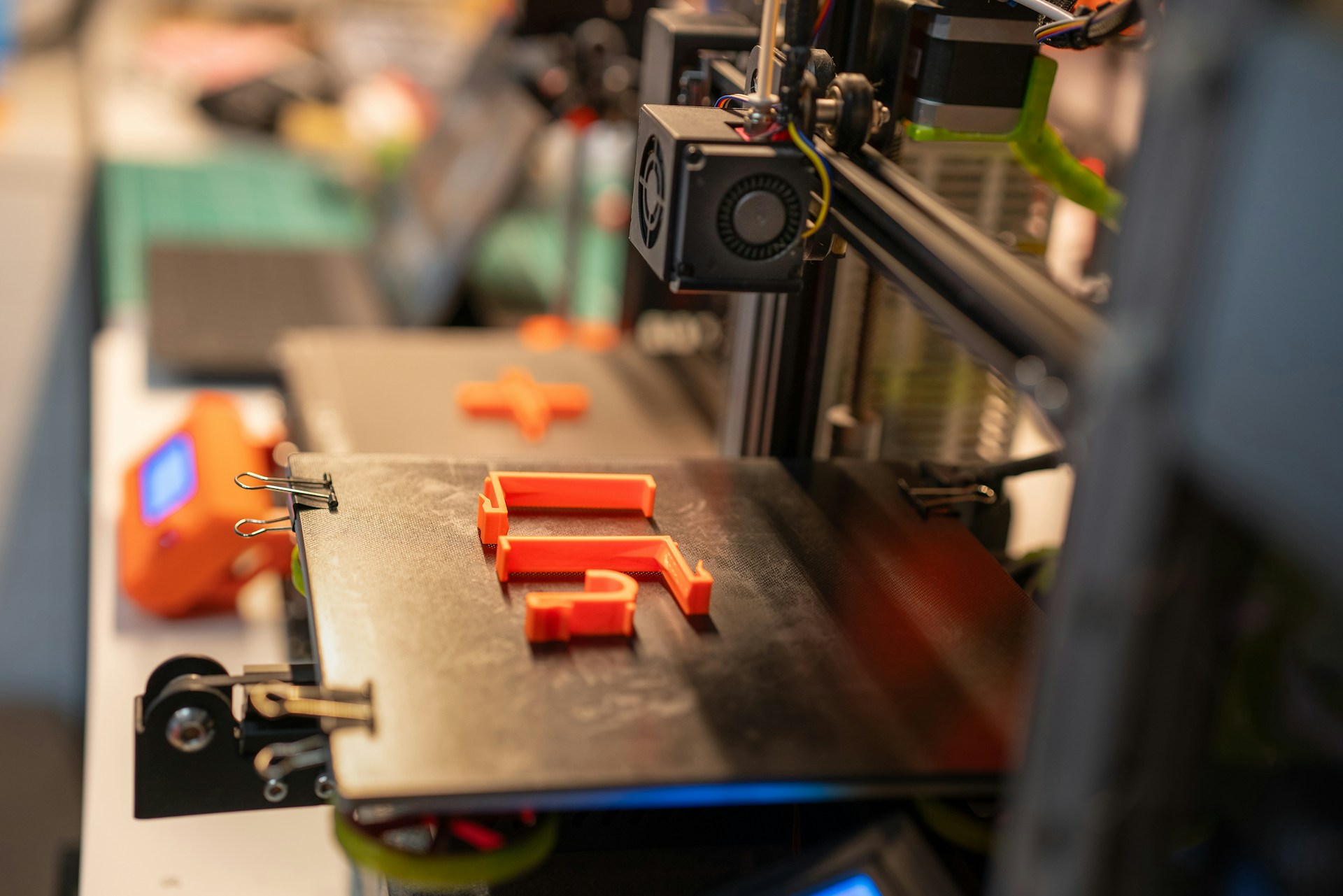

As 3D printing continues to grow in popularity, it’s essential for beginners to familiarise themselves with the key terms and concepts that define this innovative technology.

Whether you're diving into 3D printing for the first time or looking to deepen your understanding, having a clear grasp of the terminology will enhance your experience and help you achieve better results.

This guide will walk you through the essential terms and concepts every beginner should know.

3D Printing Filament

3D printing filament is the material used in most desktop 3D printers – these filaments come in various materials, each offering different properties suitable for specific applications. Some of the most common filament types include:

- PLA (Polylactic Acid): A biodegradable, plant-based plastic that's easy to print with and ideal for beginners due to its low printing temperature and minimal warping. PLA 3D printing filament is commonly used for prototypes, hobbyist projects, and decorative items.

- ABS (Acrylonitrile Butadiene Styrene): Known for its toughness and heat resistance, ABS is often used for functional parts but can be more challenging to print due to its tendency to warp.

- PETG (Polyethylene Terephthalate Glycol): PETG combines the ease of PLA with the strength and durability of ABS, making it a popular choice for functional and durable prints.

Slicer Software

A slicer is the software that converts 3D models into instructions (called G-code) that the printer can understand. It slices the digital 3D model into individual layers and provides settings for print speed, layer height, temperature, and more. Some popular slicer software includes Cura, PrusaSlicer, and Simplify3D.

G-code

G-code is the language that 3D printers use to operate – it contains the instructions for moving the print head, controlling the extrusion of the filament, and adjusting settings like temperature and speed. The slicer software generates this code, which is then sent to the printer.

Layer Height

Layer height refers to the thickness of each individual layer in a 3D print – this setting plays a crucial role in print quality and speed. A smaller layer height results in finer details and a smoother finish but increases the print time. Conversely, a larger layer height speeds up the process but may sacrifice detail. Common layer heights range from 0.1 mm (fine) to 0.3 mm (coarse).

Extruder

The extruder is the component responsible for feeding the filament into the printer's hot end, where it is melted and deposited layer by layer to create the object. There are two main types of extruders:

- Direct Drive Extruder: The extruder motor is located directly on the print head, allowing for better control of filament flow.

- Bowden Extruder: The motor is mounted away from the print head, making the print head lighter and enabling faster movement.

Nozzle

The nozzle is the small metal tip through which the molten filament is extruded; the nozzle size can affect print resolution and speed. Common nozzle diameters range from 0.4 mm (standard) to 0.8 mm (for faster, less detailed prints). Smaller nozzles offer finer details, while larger nozzles provide faster prints with less precision.

Infill

Infill refers to the internal structure of a 3D print, which provides strength and support without using excessive filament. The infill percentage determines how solid or hollow a print is. For example, a print with 20% infill will have a hollow structure with just enough support for the outer layers, while a print with 100% infill will be completely solid. Infill patterns, such as grid, honeycomb, and cubic, can also influence strength and print time.

Support Structures

Support structures are temporary scaffolding added to a print to support overhanging or complex geometries. Once the print is complete, these supports can be removed. Certain designs require support to prevent the printed material from sagging or failing. Cura and other slicers allow you to customise the placement, density, and pattern of support structures.

Bed Adhesion

Bed adhesion refers to how well the first layer of a 3D print sticks to the build plate. Good adhesion is essential to avoid warping and failed prints. Techniques for improving bed adhesion include using a heated bed, applying glue or tape, or adjusting the print temperature.

Bridging

Bridging refers to the ability of a 3D printer to print material across gaps without support structures (this is useful for certain designs where overhangs or arches are involved). The quality of bridging depends on the material, cooling, and slicer settings.

Warping

Warping occurs when the edges of a print curl or lift off the build plate, usually due to uneven cooling of the material. Filaments like ABS are more prone to warping, while PLA tends to have better adhesion. Solutions to prevent warping include using a heated bed, improving bed adhesion, and controlling ambient temperature.

Raft, Skirt, and Brim

These are three different methods used to improve bed adhesion or stabilise a print:

- Raft: A thick grid of filament placed under the print to ensure better adhesion, often used with difficult materials like ABS.

- Skirt: A line printed around the perimeter of the model without touching it, used to prime the extruder.

- Brim: A thin layer of filament added around the base of the model to increase bed adhesion and prevent warping.

Resolution

In 3D printing, resolution refers to the level of detail a printer can achieve. It’s affected by factors like layer height, nozzle size, and the precision of the printer's movement. Higher resolution prints capture more detail but take longer to complete.

Overhang

An overhang is any part of a 3D print that extends beyond the layers below it. Prints with significant overhangs may require support structures to prevent sagging or collapsing.

Understanding these essential 3D printing terms will help you navigate the world of 3D printing with confidence

Whether you're working on a hobby project or embarking on more complex designs, having a firm grasp of these concepts ensures better print quality and fewer frustrations along the way. Happy printing!