How to Integrate Palletizing Cobots into Your Existing Workflow

Integrating palletizing cobots into your existing workflow can revolutionize your production process, leading to increased efficiency, precision, and overall productivity. These robots, designed to handle repetitive tasks with high accuracy, offer a significant advantage in modern manufacturing and logistics.

In this article, we will delve into the process of integrating palletizing cobots, providing a comprehensive guide to understanding their benefits, planning for their implementation, and optimizing their use within your existing systems.

Overview of Palletizing Cobots

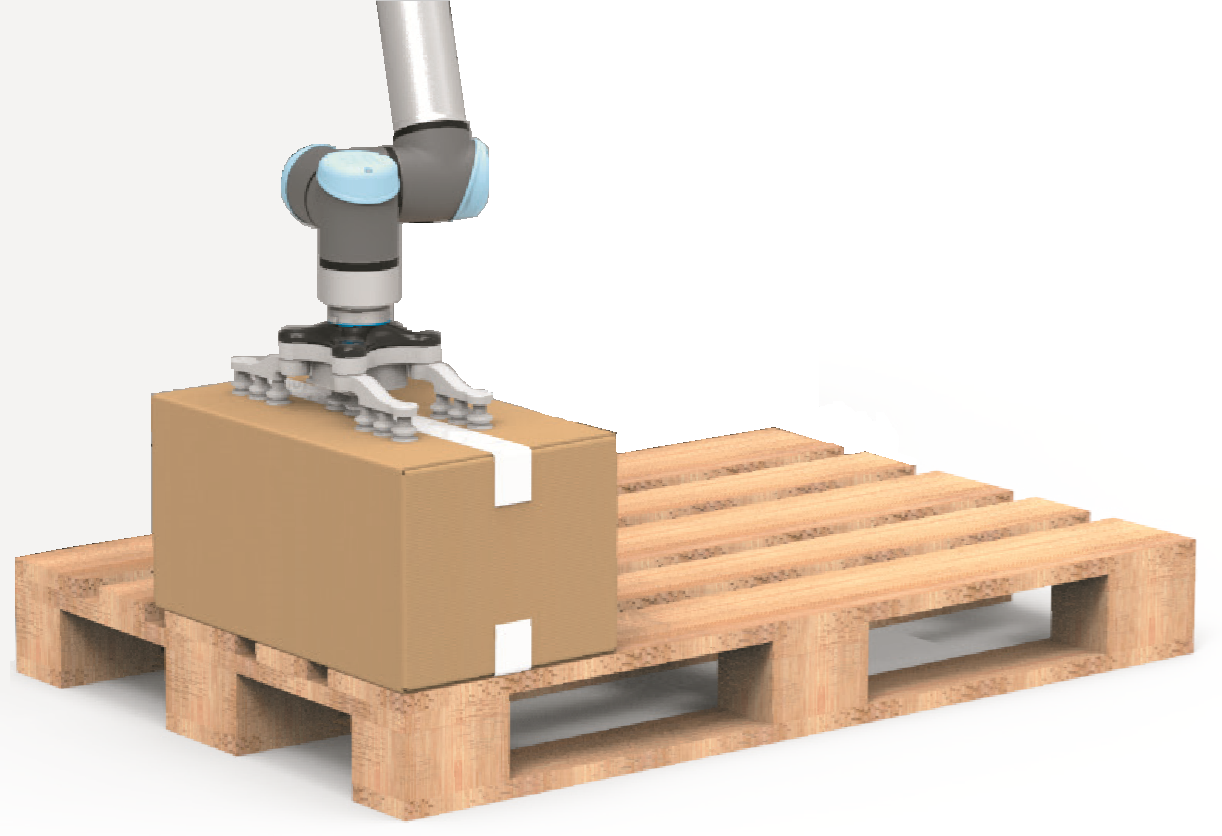

Palletizing cobots, or collaborative robots, are automated systems specifically designed to handle the task of arranging goods onto pallets. These robots are distinguished by their ability to work safely alongside human operators, adapting to various tasks with ease. Over time, the evolution of cobots has been marked by advancements in technology that enhance their precision, flexibility, and ease of integration into existing workflows. Their introduction into manufacturing processes has transformed the way companies approach repetitive tasks, driving improvements in productivity and operational efficiency.

The term palletizing robot is often used interchangeably with palletizing cobots. These robots are equipped with advanced sensors and software that enable them to handle complex palletizing tasks with high precision. They can manage various types of products, from small and delicate items to larger and heavier goods, adapting their grip and placement based on the specific requirements of the task. This capability allows for easier reconfiguration and adaptation to different tasks or production lines.

Importance of Integration

Integrating palletizing cobots into your existing workflow is not merely about adopting new technology; it’s about transforming how your operations function. The integration of these cobots can lead to substantial benefits, including enhanced accuracy in palletizing tasks, reduction in labor costs, and the ability to handle tasks that are strenuous or monotonous for human workers. By seamlessly incorporating cobots into your workflow, you can expect a notable increase in throughput and a reduction in errors, ultimately driving more efficient operations and a stronger return on investment.

Understanding Palletizing Cobots

To successfully integrate palletizing cobots, it is essential to first understand what they are and how they function. These robots are equipped with advanced sensors and software that enable them to handle complex palletizing tasks with high precision. They can manage various types of products, from small and delicate items to larger and heavier goods, adapting their grip and placement based on the specific requirements of the task.

One of the key advantages of palletizing cobots is their ability to work collaboratively with human operators. Unlike traditional robots that require safety cages and extensive setup, cobots are designed to operate safely near humans, enhancing their flexibility in the workspace. This capability allows for easier reconfiguration and adaptation to different tasks or production lines. Additionally, the cost-effectiveness of cobots, combined with their relatively simple programming and maintenance, makes them an attractive option for many businesses looking to automate their palletizing processes.

Assessing Your Current Workflow

Before integrating a palletizing cobot, a thorough assessment of your current workflow is crucial. Begin by mapping out the existing processes to gain a clear understanding of how tasks are performed and where inefficiencies may lie. This analysis will help identify bottlenecks or areas that could benefit from automation, allowing you to pinpoint the greatest potential for cobot integration.

Determining the right integration points involves evaluating where a cobot can offer the most value. Consider tasks that are repetitive, time-consuming, or prone to human error. Align the capabilities of the cobot with these tasks to ensure that the integration will address the specific needs of your workflow. This strategic approach will facilitatea smoother integration and maximize the benefits of the new technology.

Planning the Integration

Effective planning is essential for a successful integration of palletizing cobots. Start by setting clear goals and objectives for what you hope to achieve with the new system. Define the success metrics you will use to measure the effectiveness of the integration, such as improvements in processing speed, accuracy, and overall productivity.

Choosing the right palletizing cobot involves evaluating various models and manufacturers. Factors to consider include the cobot’s load capacity, reach, speed, and compatibility with your existing systems. Each model offers different features and capabilities, so selecting one that aligns with your specific requirements is critical for achieving optimal results.

Preparing Your Facility

Preparing your facility for the integration of palletizing cobots involves several considerations. Ensure that there is adequate space for the cobot to operate effectively, taking into account its range of motion and any necessary clearances. The layout of your facility may need to be adjusted to accommodate the cobot and optimize its movement within the workflow.

Additionally, address any infrastructure requirements, such as electrical and mechanical needs, to support the new system. Implementing safety protocols and ensuring compliance with relevant standards is also crucial. This preparation will help create an environment where the cobot can operate safely and efficiently, minimizing disruptions to your existing processes.

Conclusion

Integrating palletizing cobots into your existing workflow offers a range of benefits, from increased accuracy and efficiency to enhanced productivity and cost savings.

By understanding the capabilities of these robots, assessing your current workflow, and planning and executing the integration process effectively, you can achieve significant improvements in your operations.

As technology continues to advance, staying informed about emerging trends and innovations will help you maintain a competitive edge and leverage the full potential of palletizing cobots in your business.